Metrology

As a leading manufacturer of tight-tolerance and critical-use products, we need an equally sophisticated system, precise instruments and well-thought out test instructions to support our burgeoning business. In order to achieve this, we proactively approach quality excellence through the following key areas.

- Real-time Statistical Process Control

-

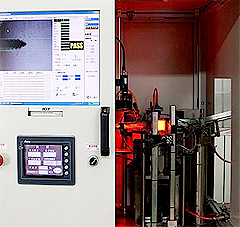

In order to increase process visibility and predict the significant deviations which may cause rejected parts, INTAI deploys real-timeStatistical Process Control. Our method is to computerize data collection from key processes and tests. Then, the data is fed automatically into our SPC software, which is equipped with real-time feedback function to notify all appropriate personnel when the control limits are not met. In this case, a much-needed action plan can be determined. Moreover, the data can be further analyzed for continuous improvement, which leads to minimum inspection costs in the future.

When you partner with INTAI, you can count on the highest quality built in each part.

- Optimizing Inspection

-

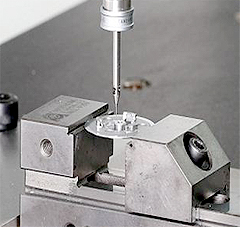

The demand for ensuring quality parts fabricated has risen every year. Consequently, robust validation protocols are developed. From a metrology perspective, INTAI strives to bring optimum inspection to eliminate human error and enhance precision measurement. INTAI QC labs use inspection instruments with high performance 3D technology, multi-sensor for contact or non-contact measurements as well as high resolution profile scanning to feature-specific gauges. All instrumentations are fully programmed, automated and calibrated regularly, ensuring all measurements are absolutely accurate, repeatable, and reproducible.

- Regular Staff Training & Development

-

INTAI’s commitment to quality also is demonstrated through the extensive staff training. Trainings are held regularly and are often associated to the latest customer requirements and advanced manufacturing techniques. Also, hiring Six Sigma certified project leads and engineers plays a critical role of leading the continuous improvement throughout entire organization. Our employees are equipped with the necessary skills to provide professionalism in every aspect of our business.

- Systematic Problem Solving

-

No matter if it is a customer complaint, out-of-controls or out-of-specs, INTAI utilizes a systematic approach to solve problems. Our cross functional team relies on Six Sigma tools to locate the source of the problem in order to determine the most effective solutions. Common tools you may see here are FMEA, DOE, 8 Disciplines (8D) Process and Fishbone Diagrams.