Quality

We are committed to delivering products and services of the highest quality. Our comprehensive quality management system aligns with international standards across various industries, including:

- General Manufacturing: ISO 9001

- Medical Devices: FDA 21 CFR 820, EN ISO 13485, ISO 13485

- Automotive: IATF16949

- Aerospace: AS9100D, JISQ9100, EN9100

This unwavering commitment to excellence ensures that every component we produce meets stringent industry specifications, providing our clients with exceptional accuracy and reliability throughout every stage of their projects, from initial design to final production. We believe it’s our duty to reduce any risks for our customers, including maintaining sustainable operations to consistently deliver quality products. INTAI acknowledges that contributing to society and the environment supports sustainable business growth. Corporate Social Responsibility (CSR) and Environmental, Social, and Governance (ESG) principles are both our certifications and our commitments.

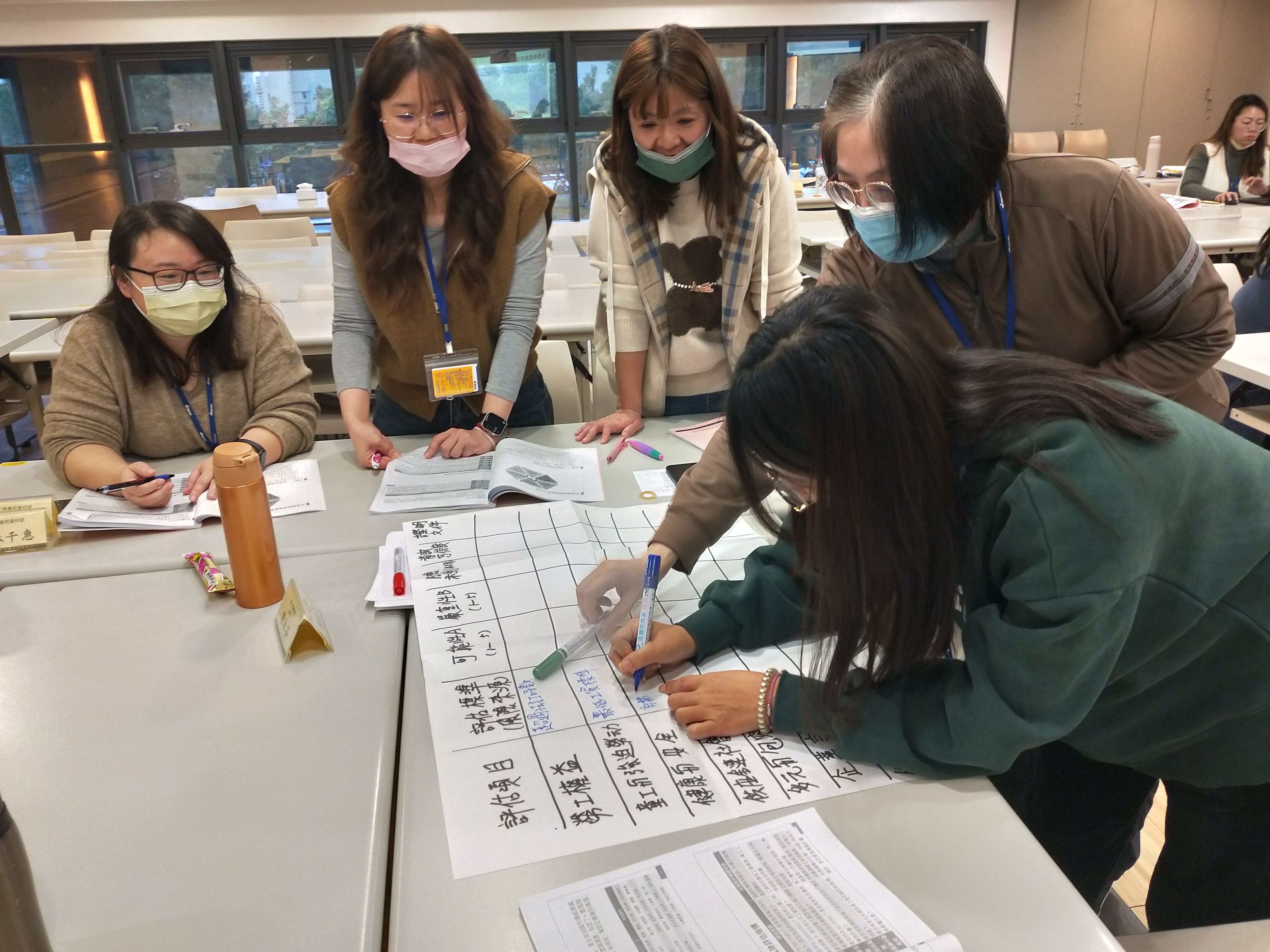

Regular Staff Training and Development

INTAI’s commitment to quality also is demonstrated through the extensive staff training. Trainings are held regularly and are often associated to the latest customer requirements and advanced manufacturing techniques. Our employees are equipped with the necessary skills to provide professionalism in every aspect of our business.

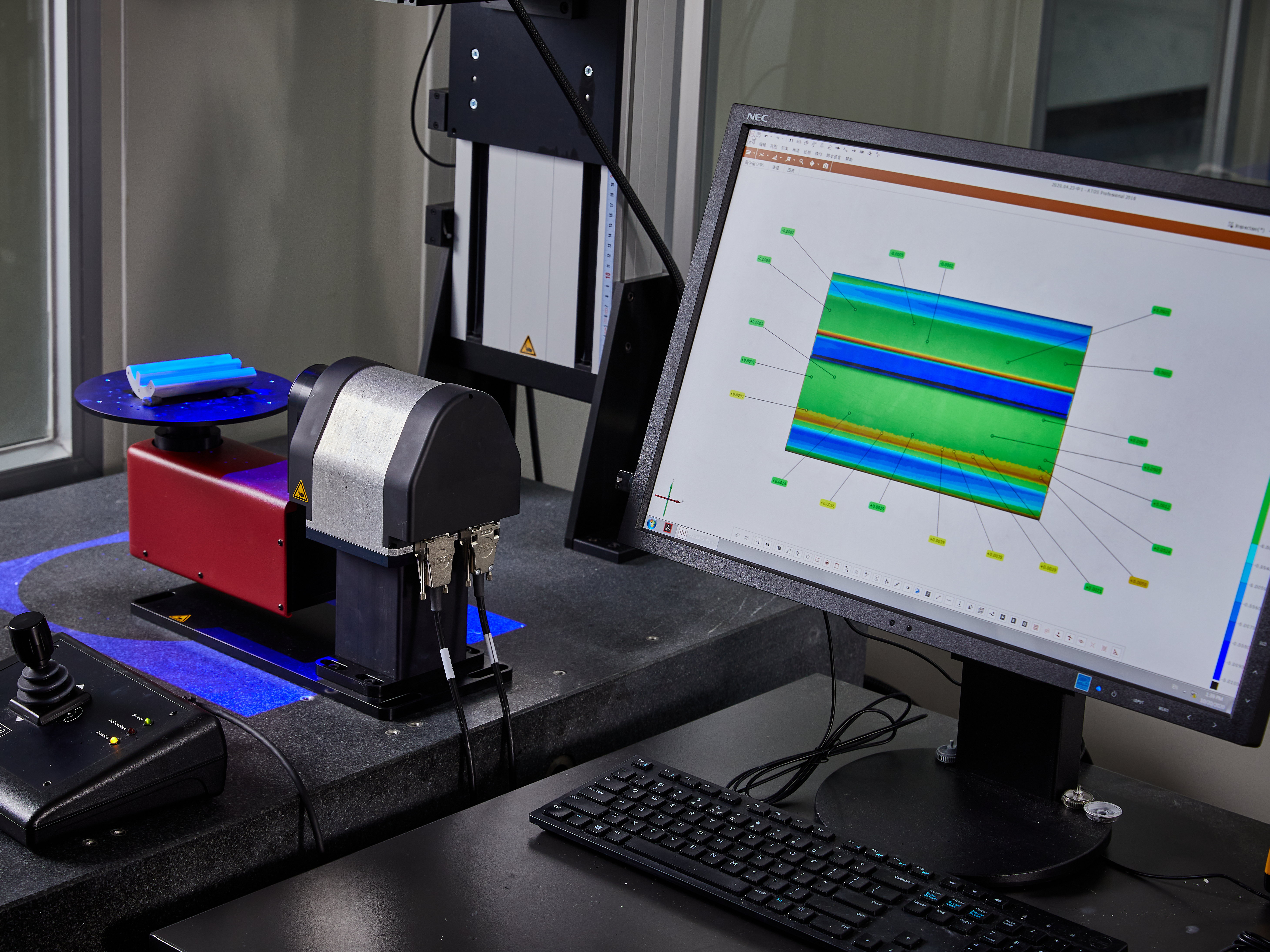

Advanced Inspection Gages and Tools

We have vision measuring, coordinate measuring, optical imaging and 3D metrology in place. Customized automatic inspection machine to provide a stable and reliable result.

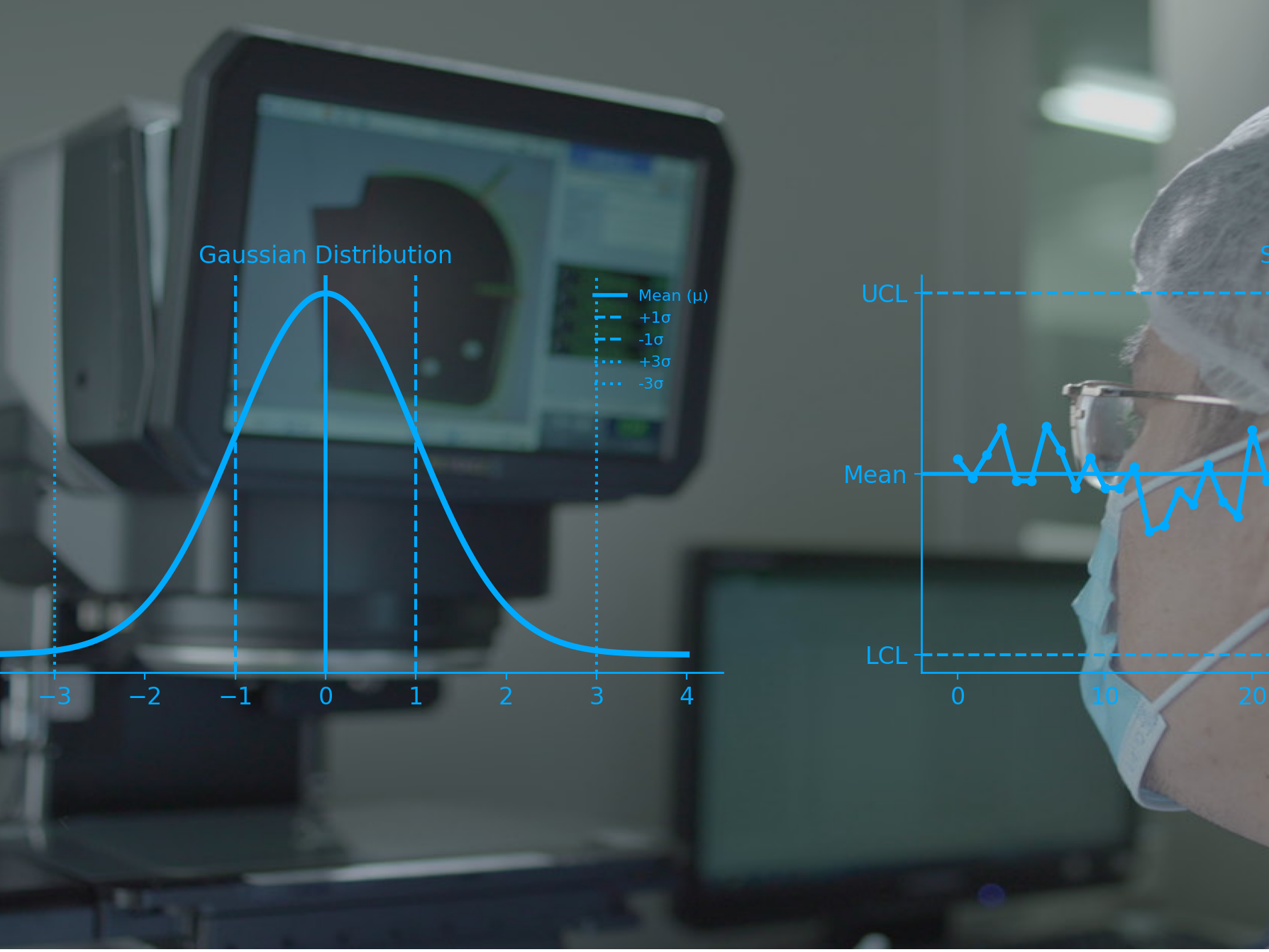

Real-time Statistical Process Control and Monitoring

INTAI deploys real-time Statistical Process Control by automating data collection from key processes and tests. This data is seamlessly fed into our SPC software, which provides real-time feedback to notify relevant personnel when control limits are exceeded, ensuring timely action and continuous process improvement.