Implant

Our implant business is committed to providing high-quality services for a diverse range of medical implantable devices. We specialize in high-precision metal fabrication and advanced plastic molding, ensuring that each product meets the highest standards of performance and safety.

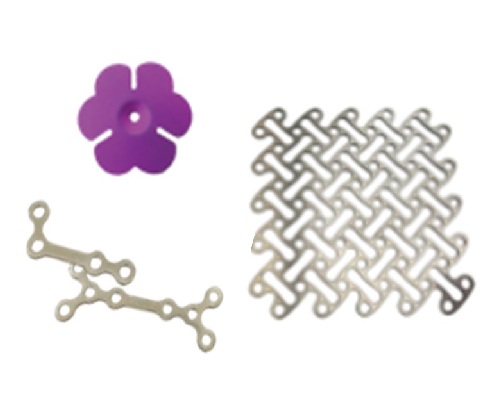

Customized Implantable Product Development

We offer end-to-end services, including design, development, and manufacturing of custom implantable products tailored to meet the specific needs of our clients. Our product offerings include dental implants, trauma implants, and other specialized medical implants that require precise engineering and the use of advanced materials. We work closely with our clients to ensure compliance with ISO 13485 and regulatory standards, delivering innovative, reliable, and cost-effective solutions.

Our product portfolio spans various medical fields, including:

- Dental

- Trauma

- Spine

- Sports Medicine

- Instruments

Advanced Manufacturing Capabilities

We pride ourselves on our state-of-the-art manufacturing facilities and a team of highly skilled engineers. Our advanced capabilities enable us to offer cost-effective, high-quality solutions that allow our clients to bring advanced medical implants to market with efficiency and precision. Some of our key manufacturing features include:

- ISO 7 Cleanroom: or FED-STD-209 E Class 10,000

- Laser Welding: Min. Welding Spot Ø0.006

- Laser Cutting: Min. Tube OD0.018”

- Plastic Injection Molding: Over 30 million shots

- Over Molding: Multi-Material Combination

- Metal Injection Molding: High Density 98%

- Swiss Machining: 53,000,000~267,000,000 Tubes/ Rods

- CNC Milling: Precision up to 1um

- Wire EDM: Copper Wire Ø0.004"

- Vacuum Furnace: Controlled Environment Quenching & Tempering

- CNC Grinding: Over 150 million Knives

- Automatic Cleaning Line: Cleanness under 55ppm